The

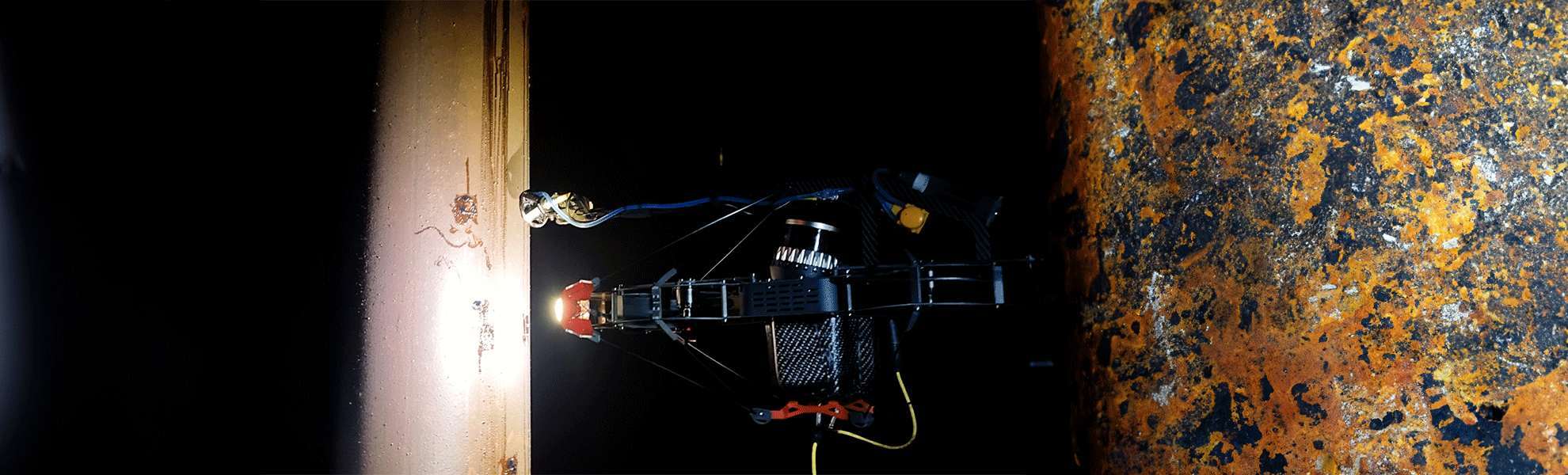

ScoutDI 137 drone system, when integrated with its UTM payload, offers significant advantages for corrosion monitoring. The UTM payload provides precise data on metal thickness, allowing for early detection of corrosion. The drone can reach areas that are difficult, dangerous, or impossible for humans to access, such as high structures, confined spaces, and hazardous environments. By using the drone to perform inspections, workers are not exposed to potentially dangerous conditions, reducing the risk of accidents. The ScoutDI 137 drone system can quickly cover large areas, providing comprehensive data in a fraction of the time it would take for manual inspections.

Integrated with Scout Portal, the ScoutDI 137 Drone System UTM payload enhances visual inspection capabilities with live A-scan ultrasonic thickness measurements. Key features include: live A-scan for real-time evaluation, enabling on-screen assessment during flights, and a motorized probe head with smart release for precise, remote adjustments and easy disconnection. The system's tethered design provides unlimited flight time, allowing for extended inspections without battery concerns. Additionally, 3D LiDAR ensures safe operation even beyond visual line of sight with anti-collision and BVLOS support. All visual and UTM data are automatically location-tagged for detailed mapping and analysis. The system also features an IACS-compliant UTM probe, developed with Tritex NDT, offering versatility with different frequency options and a robust design for precise measurements. All collected data is integrated into the Scout Portal for comprehensive 3D visualization and easy data sharing. This advanced drone system provides accurate, early detection of corrosion, improves safety by reaching hazardous areas, and supports efficient, informed decision-making in industrial corrosion monitoring.